Metal Injection Molding (MIM) is a manufacturing process that combines thermoplastic injection molding, metal powder metallurgy, and powder metallurgy sintering, to form complex metal shapes with high precision and repeatability. The MIM process can be used to produce small and intricate parts for a variety of industries, including medical, electronics, automotive, aerospace, and consumer products.

Metal injection molding can create complex shapes with tight tolerances that are difficult to achieve with other metalworking processes, such as die casting or machining. Metal Injection Molding allows to obtain complex shapes directly from the compacting tooling, without any machining operation, like teeth, splines, profiles, frontal geometries, etc.

Achievable tolerances in the perpendicular direction of compacting are typically IT 8-9 as sintered, improvable up to IT 5-7 after sizing. IT 10-13 is achieved in length depending on the component geometry; additional machining operations can improve this precision.

The tool stability, the technical complexity of the production devices, and the SPC control system, give high reliability and repeatability to the mass production sintered components.

The interconnected porosity of the material can be filled with oils, obtaining then a self-lubricating bearing: the oil provides constant lubrication between bearing and shaft, and the system does not need any additional external lubricant.

The metal injection molding materials have homogeneous micro-structure in the three space directions, so properties are isotropic. Also, the solid-state diffusion mechanism applied to create the micro-structure allows to achieve compositions and materials which are impossible to obtain by melting, like composite materials made of phases insoluble or immiscible between them, or micro-insulated materials.

The manufacturing process of metal injection molding components is certified as ecological, because the material waste is very low, the product is recyclable, and the energy efficiency is good because the material is not molten. Complex shapes may require less machining and parts assembly than other metalworking processes, making metal injection molding a very cost-effective choice.

Surface of metal injection molding components is characterised by the presence of flat areas with very low roughness, interspersed with dips corresponding to the porosity. This surface state is better than that of machined wrought materials, which feature an alternate series of peaks and troughs. The lower peaks presence allows to reduce the run-in time of the components.

The internal micro-porosity of metal injection molding parts produce a damping effect on the vibration propagation.

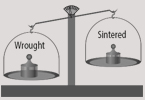

Metal injection molding parts are typically 5% to 25% lighter than the same wrought components, as a consequence of the internal micro-porosity. Parts produced with metal injection molding are strong and of high quality due to the tight dimensional tolerances it produces and the uniform distribution of metal used.

Copyright © Harber Industrial Limited All Rights Reserved. | mechanical gear ring | mim parts | powder metallurgy gears | China MIM | Sitemap

IPv6 network supported

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.