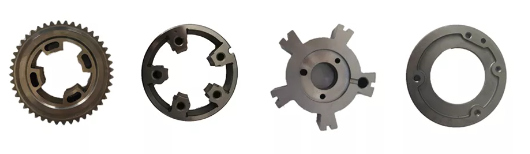

Metal powder injection molding (MIM) technology with the advantages of prominent features in producing small, complex shape parts.

Metal powder injection molding (MIM) technology with the advantages of prominent features in producing small, complex shape Stainless Steel parts. In recent years has been widely used in all walks of life. The MIM is a new metal forming process combining traditional powder metallurgy and the modern plastic injection forming technology. Metal injection molding process has strict standards for the selection of the metal powder, this is because the shape of the powder particles can control the quality of products.

Place of Origin: Guangdong, China

Brand Name: Harber or Customized

Type: Powder Metallurgy Gear Parts

Machinery Test Report: Provided

Material: Stainless Steel, STEEL

Plating:CUSTOMIZED

Product name: Customized powder metallurgy gear parts

Surface treatment: anodized, polishing, customer required

Tolerance: 0.01-0.05mm

In the past two years, China metal injection molding industry developed rapidly. It's quite common using MIM to produce airplane structural parts and car parts. Represented by MIM products of powder metallurgy parts are heavily used in the field of aircraft manufacturing, automobile anufacturing. The application of powder metallurgy technology in injection molding universality is inestimable. Metal injection molding, more and more new markets, began to try to import the MIM process. Aerospace, automotive, medical, military and all walks of life are beginning to have the MIM process production. China is a manufacturing great power. While powder metallurgy process, will face a bigger market. The traditional processing technology, will suffer from one of the most severe test.

1) Powder metallurgy can ensure the accuracy and uniformity of the material composition ratio.

2) Suitable for producing products of the same shape and large quantities, low production cost.

3) The production process is not afraid of oxidation, and no material pollution will occur.

4) No subsequent machining processing is required, saving materials and reducing costs.

5) Most difficult metals and compounds, pseudo alloys, porous materials can only be manufactured by powder metallurgy

Metal injection molding has gained popularity since its development in the late 1970s and is widely used in different industries. Some notable applications include:

Firearms: MIM is used in the production of components like triggers, safety mechanisms, magazine catches, and fire suppression systems.

Medical devices: MIM is utilized in the manufacturing of articulation gears, joint replacements, and drug delivery devices.

Automotive: MIM is employed in the production of turbocharger vanes, rocker arms, shift levers, and other automotive components.

Consumer electronics: MIM is used for manufacturing lightning connectors, heat sinks, cold plates, fiber optic parts, and various parts for mobile phones.

Aerospace: MIM finds applications in aerospace components such as flap screws, engine components, valve holders, and rocket burners.

MIM technology's ability to combine multiple operations also contributes to significant time savings for manufacturers.

1. For a design expert or a big company with your own engineering team: we prefer to receive a fully RFQ pack from you including drawing, 3D model, quantity, pictures;

2. For a start-up company owner or green hand for engineering: just send an idea that you want to try, you don't even need to know what sintering is;

3. Our sales will reply you within 24 hours to confirm further details and give the estimated quote time;

4. Our engineering team will evaluate your inquiry and provide our offer within next 1~3 working days.

5. We can arrange a technical communication meeting with you and our engineers together anytime if required.

Since 2010, Harber has been a manufacture of powder metallurgy products for a wide range of industries, such as Power Tools, Industrial Equipment, Medical Device, Locks, Car Accessories lawn and garden tools . We specially work with iron, stainless steel based metal parts.

Previous :

无Next :

Stainless Steel Sintered Gear Metal Powder InjectionIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

New Products You may like

Sintering MIM Electronic Components Earphone Shell Metal Parts read more

Stainless Steel Sintered Powder Metallurgy Mechanical Brass Gear read more

Stainless Steel Sintered Powder Metallurgy Metal Gears read more

Stainless Steel Sintered Powder Metallurgy Metal Gears read more

Stainless Steel Sintered Powder Metallurgy Mechanical Gear Ring read more

Copyright © Harber Industrial Limited All Rights Reserved. | mechanical gear ring | mim parts | powder metallurgy gears | China MIM | Sitemap

IPv6 network supported

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.