Investment Casting Technology Introduction

Investment casting also called lost_wax casting. This kind of casting process can produce sophisticated parts that close to the final product shape,metal parts or fine arts and crafts while don't need or rarely need machining.It is a kind of near net shape Metal liquid forming technology, and is widely applied.

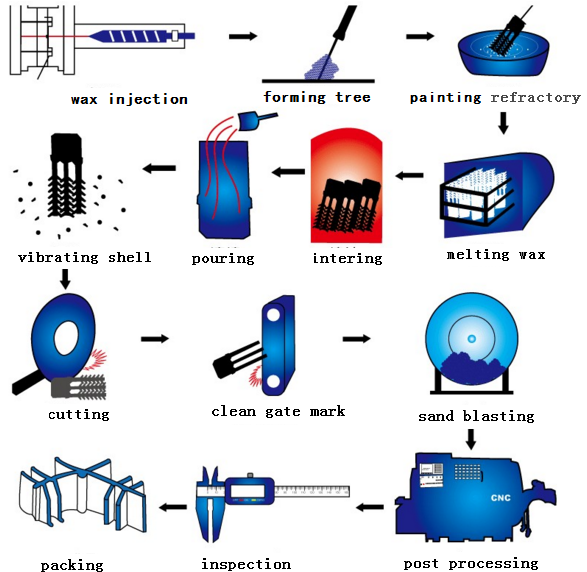

The basic processes as following:

1) Make metal mold.

2) Press the wax models on a wax mould machine with the metal mold.

3) Make wax trees by forming the wax models on the gating system.

4) Painting several layers of refractory in wax tree.

5) Get the steel shell after drying and hardening.

6) Melting the wax in the shell and let it flow out.

7) Roasting the shell and strengthen it.

8) Pour the molten liquid metal into the shell.

9) Get the casting part after the liquid metal cooling down and hardened.

10) Cut the casting parts from the trees.

11) Post_processing, surface treatment etc.

Investment casting features:

♦ Cost: molding fee low to middle, cost for unit part middle to high , labor cost is very high.

♦ Typical products:wide range of application, such as building structure, consumer electronics, aerospace, jewelry, city

sculpture, etc.

♦ Production scale: suitable for middle to larger volume production.

♦ Quality: high precision molding surface, especially suitable for metal parts with complex shape.

♦ Cycle; very long(24 hours for forming).

Not only suitable for all ferrous and non_ferrous alloys, but also good for superalloy that the traditional casting can not make. The most commonly used material is low alloy steel, stainless steel, aluminum, titanium, zinc, copper, nickel alloy and precious metals.

Part wall thickness is decided by the alloy materials used

1,Wall thickness of aluminum alloy and zinc alloy parts should be controlled between 1.5 mm - 3 mm (0.079” to 0.118”)

2. The steel and copper alloy parts wall thickness should be greater than 3 mm (0.118”)

3. Lost wax casting made up for the vacancy of traditional casting, allow parts appear inscribe and variational wall thickness and other complex situation.

Copyright © Harber Industrial Limited All Rights Reserved. | mechanical gear ring | mim parts | powder metallurgy gears | China MIM | Sitemap

IPv6 network supported

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.