Plastic Insert Tooling and Injection MIM Parts Projects

Project development Time: Dec 2022

Industry: Communication hardware industry

Used material: SS304L

Qty: 200,000pcs per year

Benefit: Cost Saving

Main Forming Process: Metal Injection Moulding

Client Introduce: The company is one of the Chinese leading communication equipment companies offering a diverse models of communication chassis products and services in Telecommunication company, computers and phones.

We have cooperate with Shenzhen Dongchuang for almost 3 years which integrates precision mold manufacturing, plastic product injection molding, automatic spraying, screen printing, assembly and other processes, specializing in the manufacturing of precision products such as router shell, communication equipment plastic structural parts, office/home intelligent equipment plastic structural parts.So naturally, they will provide drawings, we will quote and then bid, and finally select us to make this product.

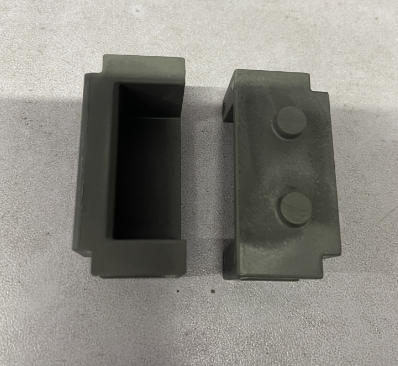

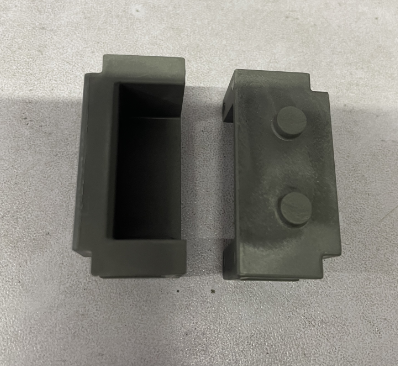

After discussed with engineer MR.Qian, we learned that the parts will be insert a plastic tooling and inject together with a very big plastic components. So the total length and the wall are the key dimension control points.

This part used SS304L with high physical properties with 35mm*22mm*8mm, weight 25g. Harber MIM delivery the ripe experienc

The plastic insert is designated as material SS304L , which is a stailess steel.It is widely used in daily life, and the material could pass 48 hours of salt spray test. Harber MIM process uses this a lot, and the cost of raw materials is the same as that of iron-based parts.

In order to control the quality, we developed a tooling with 2 cavities marked 1 and 2.It need at least 3 steps to reshape and correct the profile. We made a gauge to test the correction one by one. Please see below picture.

MIM process is very suitable for the mass production and could save a lot cost, and have stable quality tolerance.

Please contact us if you want to learn more about Harber MIM technology through sales@harber-mim.com.

Copyright © Harber Industrial Limited All Rights Reserved. | mechanical gear ring | mim parts | powder metallurgy gears | China MIM | Sitemap

IPv6 network supported

Send A Message

Send A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.